Identifying Faulty Wiring in Your Central Air Electrical System: A Professional Diagnostic Guide

Assessing Electrical Integrity in Central Air Systems

The central air electrical network is a complex infrastructure that demands precision and regular assessment. While mechanical failures often garner the most attention, electrical degradation is frequently the root cause of premature compressor failure and control board malfunctions.

Detecting faulty wiring requires a systematic approach to diagnostics. For the professional technician, this involves identifying high resistance points and insulation breakdown. For the homeowner, it means recognizing early signs of faulty electrical wiring before they escalate into catastrophic system loss.

1. Visual Diagnostics and Physical Degradation

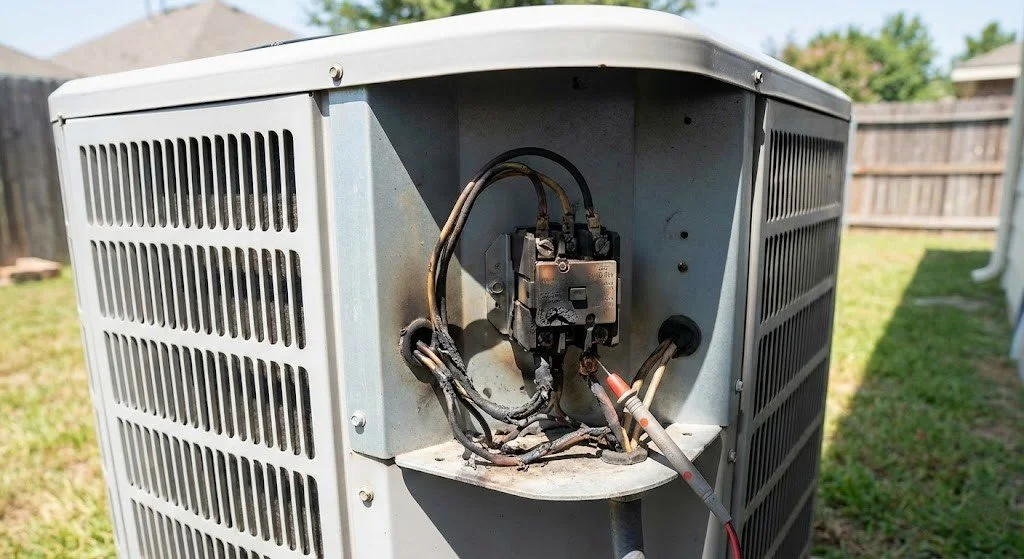

A comprehensive inspection begins with a physical audit of all conductors and terminals. The environment surrounding an outdoor condenser is inherently hostile to wiring due to thermal cycling and UV exposure.

Insulation Compromise: Professional assessment often reveals conductor exposure due to local wildlife or vibration against the cabinet. Any breach in the wire jacket is a primary safety hazard and a point for potential short to ground scenarios.

Thermal Discoloration: Discolored or carbonized wire jackets at the contactor or terminal block are definitive indicators of excessive heat. This is typically the result of loose terminations creating high resistance.

Oxidation and Corrosion: In coastal or high humidity regions, central air electrical terminals are prone to oxidation. This buildup increases resistance, leading to voltage drops that force the motor to draw higher amperage, eventually overheating the windings.

2. Audible and Olfactory Indicators of Failure

A system in distress often produces specific sensory signatures that point toward faulty wiring or component fatigue.

Contactor Chattering: A rhythmic buzzing or rapid clicking from the control circuit often signifies pitted contact points or a voltage drop in the low voltage wiring that prevents the solenoid from seating properly.

Thermal Off Gassing: The distinct odor of ozone or burning polymers indicates an active electrical arc or a conductor reaching its melting point. This requires an immediate system lockout to prevent a structure fire.

Burnt contactor in condenser

3. Advanced Technical Troubleshooting

To truly rank the health of a system, one must look at the electrical performance under load. These are the critical areas where signs of faulty electrical wiring manifest.

Overcurrent Protection Trips

When a circuit breaker trips, it is a defensive response to a hazardous electrical condition. Frequent tripping suggests a hard start condition, a grounded winding, or a dead short within the central air electrical circuit. Testing for continuity to ground is a mandatory diagnostic step in these instances.

Capacitor Plinth and Terminal Integrity

The start and run capacitors are high stress components. Beyond physical bulging, technicians must inspect the wiring spades for tightness. A loose connection at the capacitor can cause intermittent arching, which eventually destroys the terminal and leads to a no cool call.

Voltage Drop Analysis

A professional standard for identifying faulty wiring is performing a voltage drop test across the load side of the contactor. Significant variance indicates that the internal contacts or the wire terminations have high resistance and require immediate replacement to protect the compressor motor.

Professional Electrical Diagnostic Reference

This table serves as a diagnostic standard for evaluating system health and determining the necessary corrective path.

| Diagnostic Sign | Probable Electrical Root Cause | Professional Action |

|---|---|---|

| In-rush current spikes | Failing capacitor or weak wiring | Replace capacitor / Check wire gauge |

| Recurrent breaker trips | Grounded compressor or short-circuit | ISOLATE POWER. Perform megohm-test. |

| Inductive hum / No-start | Open winding or failed conductor | Trace circuit / Check for wire continuity |

| Pitted contactor points | High-arc voltage or loose leads | Replace contactor and re-terminate wires |

The Necessity of Precision Wiring

System performance is tethered to the quality of the central air electrical installation. As noted by the Department of Energy, maintaining optimal electrical conductivity ensures that high dollar components like the compressor operate within their designed amperage range.

Utilizing the correct wire gauge and ensuring all terminations are torqued to specification prevents the thermal runaway that often fries expensive HVAC control boards. Whether dealing with residential or industrial applications, the physics of wiring remains constant: poor connections equal wasted energy and equipment failure.

Conclusion

Identifying faulty wiring within a central air electrical system is a critical skill for maintaining operational uptime. By monitoring for signs of faulty electrical wiring such as thermal damage, audible chattering, and voltage fluctuations, you ensure the safety and efficiency of the entire HVAC environment.

Is your equipment showing these symptoms? Professional intervention is required whenever the electrical integrity of a system is in question. Ensure your system is locked out and tagged out before attempting any advanced diagnostics or repairs.