Troubleshooting Electric Furnace Elements & Sequencers: AC Troubleshooting Steps for Winter Heating

When the "AC" Needs to Bring the Heat

We often think of "AC troubleshooting steps" as a summer activity, but for technicians and DIYers dealing with heat pumps or straight-cool units with electric backup, winter is when the real stress test happens. When the heat pump goes into defrost—or when the temperature drops below the balance point—your system relies entirely on electric resistance heat strips.

If you’ve read our guides on hopscotching or condenser diagnostics, you know how to trace power. But electric furnaces are different beasts. They deal in high-amperage resistive loads and thermal timing.

This guide moves inside the air handler to focus exclusively on the specific components that fail during winter: the sequencer, the limit switch, and the heating element itself. Here is your definitive guide to troubleshooting electric heating systems.

1. The Silent Failure: Troubleshooting the Sequencer

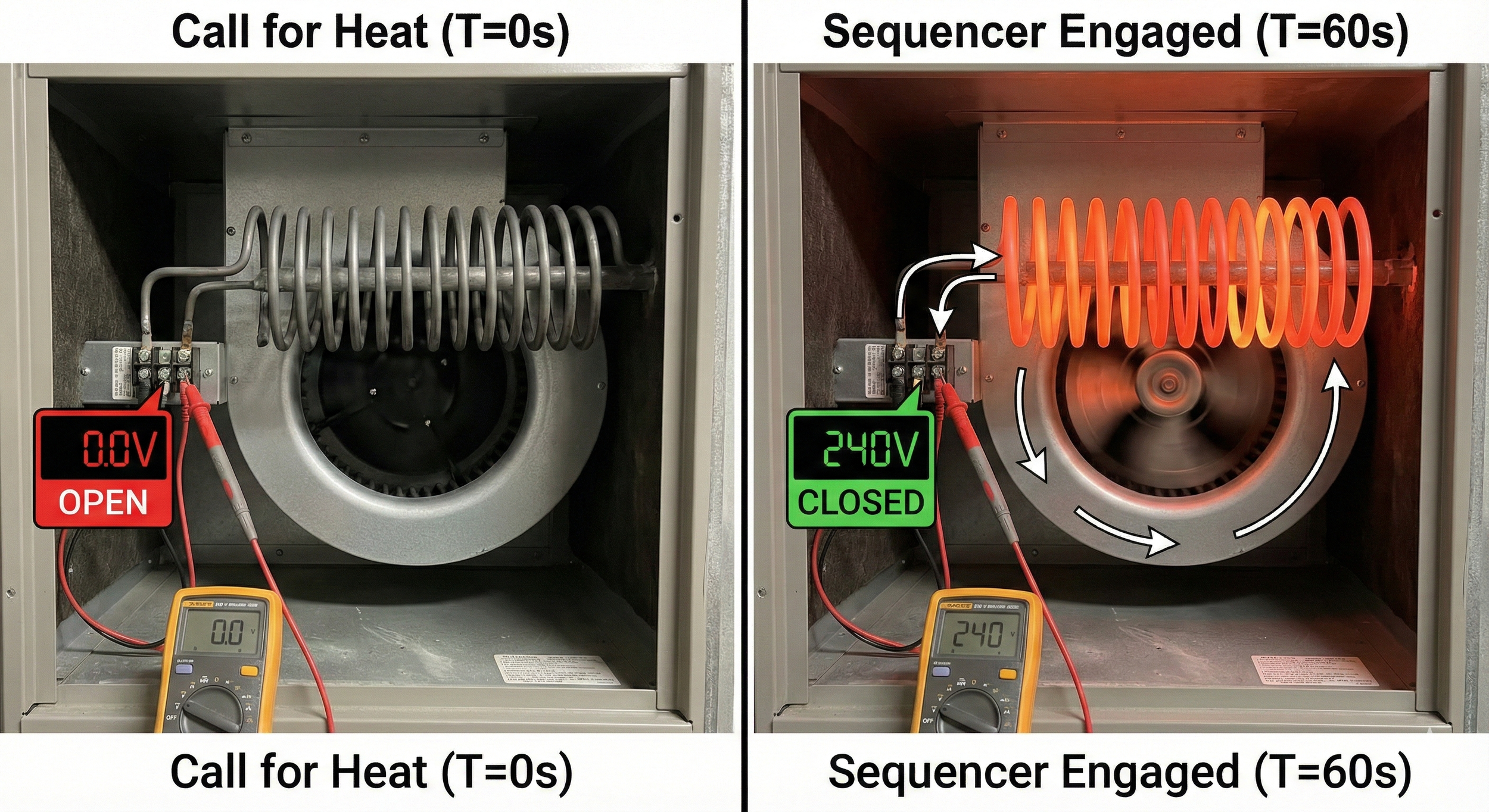

Unlike a standard contactor that snaps shut with a loud clunk, a sequencer is designed to be silent and slow. This often confuses technicians who are used to instant gratification when testing voltage.

The sequencer manages the "resistive load" (the massive power draw of the heater coils) by staging them on. If they all turned on at once, the lights in the house would dim, or the main breaker might trip.

How to Troubleshoot a Sequencer:

A sequencer has two parts: the Heater (Control) Circuit (usually 24V at the bottom) and the Switch (Load) Circuit (high voltage terminals).

Call for Heat: Verify you have 24V across the bottom terminals (often labeled M1/M2).

The Waiting Game: Do not assume it's dead immediately. Sequencers rely on a bimetal disc heating up. It can take anywhere from 30 to 90 seconds to close.

Check Continuity (Power Off): If the sequencer is hot to the touch but the high voltage terminals haven't closed (checking for 0V across the switch or continuity with power off) after 2 minutes, the bimetal disc is burnt out.

Stuck Closed: Conversely, if the thermostat is satisfied (no 24V call) but the blower and heat keep running, the sequencer contacts may have welded shut. This is a common fire hazard in older units.

Pro Tip: If you are replacing a sequencer, always mark your wires. A single sequencer can control multiple banks of heat and the blower motor. Mixing these up is the fastest way to short a low-voltage transformer.

Before-and-after diagnostic diagram illustrating HVAC sequencer timing and voltage checks when troubleshooting electric heating elements.

2. The Resistive Load: Inspecting Heating Elements

When troubleshooting furnace issues in an electric setup, the heating element is the workhorse. These are coils of resistance wire (Nichrome) that glow red hot.

The "Visual" Check (Flashlight Required):

Before grabbing your meter, look at the coils.

Sagging: As coils age, they sag. If a coil touches the metal housing or another coil, it creates a short to ground.

Breaks: Look for physical snaps in the wire. A broken wire means an open circuit—zero heat.

The Meter Check:

If you can't see the break, your meter can find it.

Kill the Power: Ensure 240V is disconnected.

Isolate: Disconnect one wire leading to the heating element to prevent reading through a parallel circuit.

Measure Resistance (Ohms): Place your leads across the element terminals.

Reading OL (Open Loop): The wire is broken. The element is dead.

Reading 0 Ohms: You have a direct short (rare on the element itself, usually implies wiring issues).

Reading 10–50 Ohms: The element is likely good.

3. The Safety Net: High Limit Switches

If your heating elements test fine, and your sequencer is closing, but the heat cycles on and off rapidly, you aren't dealing with an electrical failure—you are dealing with an airflow failure.

Limit switches are safety devices wired in series with the heating element. If the blower motor fails or the filter is clogged, the coils get too hot. The limit switch opens to cut power to the element to prevent a fire.

Troubleshooting Steps:

Check the Filter: A dirty filter is the #1 cause of electric heat "short cycling."

Amp Draw: If the blower is running but moving slow, check the capacitor and motor amp draw.

The Switch Itself: With power off, a limit switch should have continuity (Normal Closed). If it reads "Open" (OL) while the unit is cold, the switch is stuck open and needs replacement.

4. Detailed AC Troubleshooting Steps for Electric Heat (Winter Mode)

When a customer calls saying "my electric heat isn't working," follow this logical AC troubleshooting steps flowchart to diagnose the unit efficiently.

Step 1: Verify High Voltage

Electric furnaces usually have two breakers (often 30A and 60A). Check voltage at the disconnect or terminal block. You need 208V–240V.

Step 2: Verify Low Voltage (Thermostat Signal)

Remove the thermostat door. Jump R (Red) to W (White).

Go to the air handler. Do you have 24V at the sequencer control terminals?

No: Check safety switches (condensate overflow) or broken thermostat wire.

Yes: Proceed to Step 3.

Step 3: Amp Clamp Diagnostics

This is the fastest way to verify operation without touching live wires.

Clamp your meter around the thick black/red wire going to the heating element.

Zero Amps: The sequencer hasn't closed, or the element is broken.

Proper Amps: Use the formula $Amps = Watts / Volts$. A 5kW heat strip at 240V should pull roughly 20.8 Amps. If you are reading significantly lower, you may have a dropped leg of power.

Step 4: Check the Blower Interlock

Electric heating elements must have airflow. Most modern sequencers bring the fan on before or with the heat. If the elements are glowing but the fan is off, shut it down immediately. You likely have a bad blower relay or capacitor.

Summary: Don't Be a Parts Changer

Troubleshooting electric heat requires patience. The delay of the sequencer and the simplicity of the heating element can deceive you. Don't just swap the thermostat because the heat didn't come on instantly.

By isolating the sequencer timing, verifying the resistive load of the elements, and ensuring safety limits are closed, you can solve almost any electric furnace issue this winter.

Need to trace where the power is losing connection before it hits the sequencer? Check out our guide on Advanced Electrical Troubleshooting Mindset to refine your diagnostic strategy.